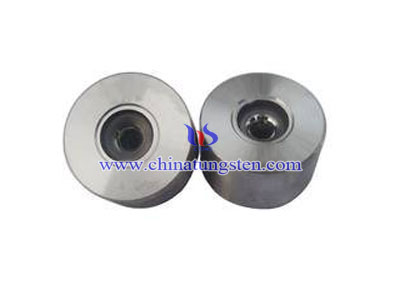

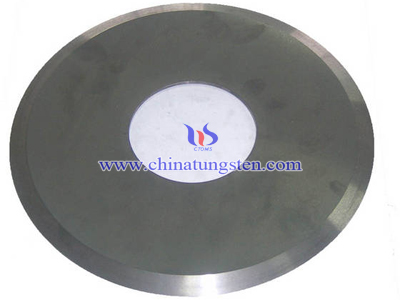

硬質合金管拉絲模

圓形、六邊形、方形和其他特殊形狀的管模具用於拉制多種材質的管材。我們還製造了多種形狀的芯軸用於保持管的內徑。

S23 硬質合金拉絲模用於拉制金屬管材::

尺寸( mm) |

參考尺寸(mm) |

||||||

D |

H |

d |

2γ |

h |

h1 |

R |

e |

15 |

10 |

2.5~3.5 |

60° |

2.5 |

1.0 |

8.0 |

2.0 |

20 |

14 |

4.3~7.9 |

60° |

4.6~5.0 |

1.0 |

9.0~10.0 |

2.0 |

24 |

18 |

8.4~12.7 |

60° |

6.2~7.3 |

1.5 |

12.0~13.0 |

2.0 |

45 |

24 |

20 |

60° |

4.0 |

2.5 |

30.0 |

1.5 |

50 |

32 |

20.0~24.0 |

60° |

12.0 |

2.0 |

30.0 |

1.5 |

60 |

35 |

26.0~30.0 |

60° |

12.0 |

2.0 |

35.0 |

1.5 |

70 |

42 |

32.0~36.0 |

60° |

15.0 |

2.5 |

35.0 |

1.5 |

75 |

42 |

38.0~40.0 |

60° |

15.0 |

2.5 |

35.0 |

1.5 |

85 |

45 |

42.0~46.0 |

60° |

15.0 |

2.5~3.0 |

40.0 |

1.5 |

100 |

50 |

48.0~54.0 |

60° |

18.0 |

3.0 |

40.0 |

2.4 |

110 |

50 |

56.0~62.0 |

60° |

18.0 |

3.0 |

40.0 |

2.4 |

125 |

55 |

64.0~70.0 |

60° |

20.0 |

3.0 |

40.0 |

2.0 |

147 |

55 |

72.0~90.0 |

60° |

20.0 |

4.0 |

50.0 |

2.0 |

168 |

55 |

91.0~113.0 |

60° |

20.0 |

4.0 |

50.0 |

2.0 |

S22硬質合金拉絲模用於拉制有色金屬管材:

尺寸(mm) |

參考尺寸(mm) |

|||||||

D |

H |

d |

2α |

2γ |

h |

h1 |

R |

e |

20 |

13 |

2.8~5.0 |

24° |

60° |

1.5 |

3.0 |

4.0 |

1.0 |

20 |

14 |

5.5~7.6 |

24° |

60° |

2.0 |

3.0 |

4.5 |

1.0 |

25 |

18 |

10.0~11.0 |

24° |

60° |

2.0 |

3.0 |

4.5 |

1.2 |

30 |

18 |

6.7~11.5 |

24° |

60° |

2.0 |

3.0 |

4.5 |

1.2 |

35 |

18 |

13 |

24° |

60° |

4.0 |

3.0 |

5.5 |

1.2 |

45 |

24 |

12.5~23.5 |

24° |

60° |

2.7 |

3.0 |

5.5 |

1.2 |

50 |

25 |

26 |

24° |

60° |

5.0 |

4.0 |

7.0 |

1.2 |

54 |

27 |

21.5~23.5 |

24° |

60° |

4.0 |

5.0 |

7.0 |

1.5 |

60 |

30 |

24.0~33.5 |

24° |

60° |

4.0 |

4.5 |

5.5 |

1.2 |

80 |

35 |

34.5~47.0 |

24° |

60° |

4.0 |

5.0 |

10.0 |

1.5 |

90 |

40 |

49.0~52.0 |

24° |

60° |

6.5 |

5.0 |

10.0 |

2.0 |

100 |

40 |

53.0~57.0 |

24° |

60° |

5.5 |

5.5 |

10.0 |

2.0 |

120 |

45 |

59.0~67.0 |

24° |

60° |

5.5 |

5.5 |

10.0 |

2.0 |

130 |

50 |

69.0~78.0 |

24° |

60° |

6.0 |

5.5 |

12.0 |

2.0 |

140 |

50 |

79.0~88.0 |

24° |

60° |

6.0 |

5.5 |

12.0 |

2.0 |

230 |

60 |

138.0 |

24° |

60° |

6.0 |

5.5 |

12.0 |

2.0 |

240 |

60 |

152.0 |

24° |

60° |

10.0 |

10.0 |

10.0 |

3.0 |

S23硬質合金拉絲模用於拉制金屬管材:

尺寸( mm) |

參考尺寸 (mm) |

||||||

D |

H |

d |

2γ |

h |

h1 |

R |

e |

15 |

10 |

2.5~3.5 |

60° |

2.5 |

1.0 |

8.0 |

2.0 |

20 |

14 |

4.3~7.9 |

60° |

4.6~5.0 |

1.0 |

9.0~10.0 |

2.0 |

24 |

18 |

8.4~12.7 |

60° |

6.2~7.3 |

1.5 |

12.0~13.0 |

2.0 |

45 |

24 |

20 |

60° |

4.0 |

2.5 |

30.0 |

1.5 |

50 |

32 |

20.0~24.0 |

60° |

12.0 |

2.0 |

30.0 |

1.5 |

60 |

35 |

26.0~30.0 |

60° |

12.0 |

2.0 |

35.0 |

1.5 |

70 |

42 |

32.0~36.0 |

60° |

15.0 |

2.5 |

35.0 |

1.5 |

75 |

42 |

38.0~40.0 |

60° |

15.0 |

2.5 |

35.0 |

1.5 |

85 |

45 |

42.0~46.0 |

60° |

15.0 |

2.5~3.0 |

40.0 |

1.5 |

100 |

50 |

48.0~54.0 |

60° |

18.0 |

3.0 |

40.0 |

2.4 |

110 |

50 |

56.0~62.0 |

60° |

18.0 |

3.0 |

40.0 |

2.4 |

125 |

55 |

64.0~70.0 |

60° |

20.0 |

3.0 |

40.0 |

2.0 |

147 |

55 |

72.0~90.0 |

60° |

20.0 |

4.0 |

50.0 |

2.0 |

168 |

55 |

91.0~113.0 |

60° |

20.0 |

4.0 |

50.0 |

2.0 |